On any active construction site, efficiency depends on dozens of small decisions made before work even begins. One of the most underestimated—but highly impactful—choices is where to place a roll-off dumpster. Poor placement creates unnecessary obstacles, slows crews down, increases safety risks, and leads to costly delays that compound over time.

When dumpsters are positioned strategically, waste removal becomes seamless, workflows stay uninterrupted, and productivity remains high. This article explains how proper roll-off dumpster positioning directly prevents delays, improves safety, and helps contractors maintain control over schedules and budgets.

Why Dumpster Placement Matters More Than Contractors Realize

Dumpsters are often treated as passive equipment: drop it somewhere out of the way and forget about it. In reality, improper dumpster placement affects nearly every aspect of daily operations.

Poor positioning can cause:

- Blocked access for workers and equipment

- Increased walking distances for debris disposal

- Congested work zones

- Safety hazards from uneven or unstable placement

- Delays during pickup or container swaps

Over the course of a project, these small inefficiencies translate into lost labor hours and rising costs.

The Hidden Cost of Poor Jobsite Flow

Every extra step a worker takes to dispose of debris adds up. Multiply that by dozens of workers over weeks or months, and the result is significant productivity loss. A poorly planned waste area forces crews to navigate around obstacles, wait for access, or manually relocate debris multiple times.

Strategic jobsite dumpster location supports:

- Faster cleanup throughout the day

- Clear pathways for people and machinery

- Reduced congestion in active work zones

- Smoother coordination between trades

When waste disposal is intuitive and accessible, crews stay focused on building—not on managing trash.

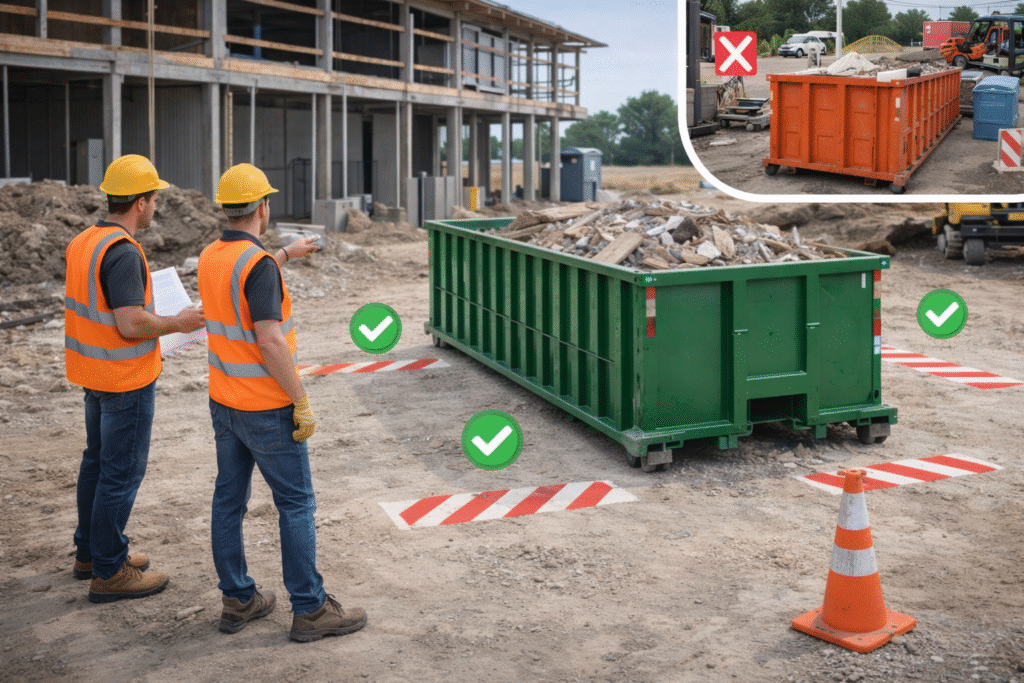

Safety Starts with Proper Dumpster Positioning

Safety issues are one of the fastest ways a project falls behind schedule. An unstable or poorly located container increases the risk of accidents, injuries, and equipment damage.

A properly positioned safe dumpster helps prevent:

- Trip and fall hazards

- Collisions with vehicles or heavy machinery

- Containers shifting on uneven ground

- Blocked emergency routes

- Unsafe lifting or dumping angles

Keeping waste containers secure and clearly accessible protects workers and reduces the likelihood of safety incidents that cause work stoppages.

Common Dumpster Access Issues That Cause Delays

One of the most frequent problems contractors encounter involves dumpster access issues. Even when a container is technically “on site,” poor access can render it inefficient or unusable.

Typical access problems include:

- Placement too close to structures or scaffolding

- Insufficient clearance for doors to open fully

- Blocked access by parked equipment

- Limited space for roll-off trucks to service containers

- Placement on soft or unstable ground

When trucks can’t safely deliver, swap, or remove dumpsters, schedules suffer. Access issues often result in missed pickups, rescheduled service, and downtime that affects the entire crew.

How Proper Placement Supports Efficient Waste Removal

Smooth efficient waste removal depends on thoughtful planning before the dumpster ever arrives. When containers are positioned with workflow in mind, debris disposal becomes a natural part of the workday instead of a disruption.

Benefits of Strategic Placement

- Shorter travel distances for debris disposal

- Faster cleanup at the end of each shift

- Reduced need for temporary debris piles

- Easier compliance with cleanliness standards

- Fewer interruptions during active work

Efficiency isn’t just about speed—it’s about consistency. Proper placement ensures waste removal happens continuously without slowing down production.

Factors to Consider When Positioning a Roll-Off Dumpster

Every project is different, but several universal factors should always guide dumpster placement decisions.

1. Site Layout and Workflow

Place dumpsters near high-debris zones while keeping them clear of primary work areas. The goal is accessibility without interference.

2. Equipment and Vehicle Traffic

Ensure containers are not positioned in routes used by forklifts, loaders, cranes, or delivery vehicles. Clear separation prevents accidents and congestion.

3. Ground Conditions

Dumpsters should sit on stable, level surfaces to prevent shifting, tipping, or damage to pavement.

4. Service Truck Access

Roll-off trucks require adequate space to deliver and remove containers. Tight corners, low clearance, or blocked paths can delay service.

5. Project Phases

As work progresses, debris zones may shift. Dumpster placement should be flexible and adjusted as needed.

The Impact of Poor Placement on Project Timelines

When dumpsters are poorly positioned, delays often appear gradually—making them harder to identify and correct. These delays show up as:

- Slower daily cleanup

- Missed disposal schedules

- Increased overtime to compensate for lost productivity

- Safety inspections triggered by clutter

- Frustration among crews and supervisors

Over time, these issues erode both morale and profitability.

Why Contractors Should Plan Dumpster Placement in Advance

Dumpster placement should be part of pre-construction planning, not a last-minute decision. Incorporating waste logistics early allows contractors to anticipate challenges and avoid costly adjustments later.

Advance planning helps:

- Align waste removal with construction phases

- Prevent conflicts with equipment staging

- Reduce the need for emergency relocations

- Ensure compliance with safety and access regulations

Proactive planning is always less expensive than reactive problem-solving.

How IVAN’S SITE SERVICES Supports Smarter Dumpster Placement

Professional site service providers bring experience and insight that contractors may not have time to develop internally. IVAN’S SITE SERVICES works with contractors to identify optimal container placement that supports workflow, safety, and service reliability.

Advantages of Professional Placement Support

- Assessment of site layout and access points

- Guidance on container size and positioning

- Reliable servicing without access delays

- Flexible adjustments as the project evolves

- Reduced risk of downtime and safety issues

Expert support ensures waste removal enhances productivity instead of hindering it.

Conclusion

Roll-off dumpster placement is not a minor logistical detail—it’s a strategic decision that influences safety, efficiency, and project timelines. When containers are positioned thoughtfully, waste removal becomes seamless, crews work faster, and delays are minimized. By planning ahead and partnering with experienced site service professionals, contractors can eliminate unnecessary obstacles, protect productivity, and keep projects moving forward without disruption.